Assignment 3: Critical reflection

Overview reflection:

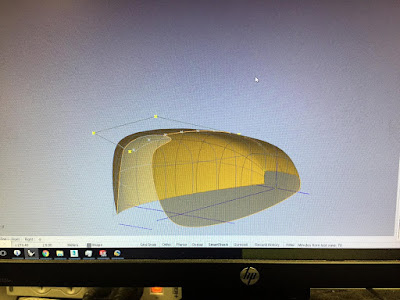

After a whole semester's study on BEIL0014 Digital Making, i got full experience on modern craft technique. It can take use on 3D laser printer to design original product model during production. English wheel has overturned my impression on planishing, in my first thought, only point hammer can make the object some curve and rub it with sand paper to do surface finishing, though mallet's effect in the progress is still vital. Besides, some supplement devices is also play great role when producing, the more suitable tools or device you choose in appropriate condition, the ideal result is quick to reach and so that less time it required. The tray i made can strongly prove it, which make me learn most from the course, it is also the reason why i choose it to review.

For the cross discipline feature it claimed, what you gain from other discipline is important. During the communicate and co-operation with most architect and industrial design mates, they usually generate flexible and suitable method base on different condition rather than traditional method. Even use old way there is always some new attempt or improve on it. It is cool actually, because my discipline is construction management, which is more concentrate on the paper work and usually reference for the article which is most reputation, in this progress i always mistake on whether it is fit on my topic and ignore the effect of demonstration during the project. It is the main spirit i learn from the workshop. And for the technique, maybe the edit skill on 3D laser printer might help me much more in future career. When i really want to present some property to the client, with reasonable time and energy, it is possible to bring the imagine site from visual to reality, which might offer a good evidence for describe and introduce the solid property to the clients and shareholders.

Review project: The Tray

Key Process:

1.Collect the key material-2 aluminium plates and 2 timber rectangle mould

2.Rub out the angle of the timber mould to smooth and with specific radian under standard

3.Place mark on the aluminium plate used to build up the border of tray

4.Use the modified mould to mark out the 4 angle of aluminium plates and cut out the sharp part and like the mould

5.Fix 2 moulds and a marked plate together like burger on the specific device, and try to smash it and make it as vertical as possible the the plate[IMPORTANT]

6.Cut the redundant part of the corner and planishing in order to make 2 aluminium tray combine perfectly

7.Smooth it with sand paper and Brasso

7.Smooth it with sand paper and Brasso

Compared with last 2 project, this project produce more difficulty on understand of conductivity, shrinkage and the smash accuracy on the material. Conclude the failure experience, i fixed it on the table with 2 fixators, because there is only 2 reasonable fixed device can be applied and there is whole class waiting to use. This method is exposed to many problem when i shaped the tray. 2 single phases can not keep the burger much stable in ideal, and it can only offer one surface to me to work, many loose and tight fixator movement required, which caused it is so easier to make the wrong smash and reduce the quality and the efficiency. As result, i was failed on 2 material.

Compare to first time i attempt, it offer a much comfortable experience on smash work but still have difficulty. Despite of making the border of the sides, the shaping on corner is most difficult part in this project. Whether it begin from the length side or the wide side, the other side will be influenced. It is required to offer equal pressure to each side, once put more strength at one side, the other side will produce a small gap, and this gap might really affect the overall performance of the project. Besides, after hammer, there is a little glitch that it is quite hard to get your tray out of the mould, i finally pry it out but it make a bit shape change, and i try my best to overcome this shortcoming but it still looks not much pretty. And aim to enhance the finish effect, i choose to use sand paper and Brasso to make it more smooth.

Compare to first time i attempt, it offer a much comfortable experience on smash work but still have difficulty. Despite of making the border of the sides, the shaping on corner is most difficult part in this project. Whether it begin from the length side or the wide side, the other side will be influenced. It is required to offer equal pressure to each side, once put more strength at one side, the other side will produce a small gap, and this gap might really affect the overall performance of the project. Besides, after hammer, there is a little glitch that it is quite hard to get your tray out of the mould, i finally pry it out but it make a bit shape change, and i try my best to overcome this shortcoming but it still looks not much pretty. And aim to enhance the finish effect, i choose to use sand paper and Brasso to make it more smooth.

The correct method: fix device

Finished mould after rubbing

The 'burger'

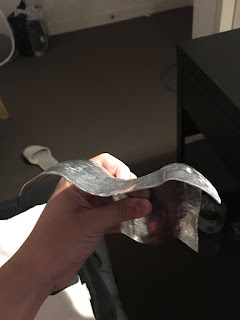

Try to combine them

First fail work

Second attempt with new method

Mark on the plate and cut off angle

Taped them together better to be rubbed

Sand paper for finishing work

Brasso for finishing work