Team up with:

Xujie Feng(Jay) z5042594

Yuqing Wu(Maggie) z5027269

Key Procedures:

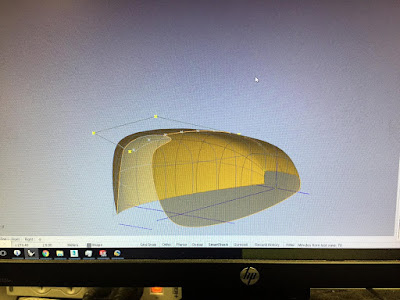

1.Edit the

digital fuel tank template on software(Rhino)

2.Import the template data to 3D

laser cutting machine and produce a timber model for reference

3.Use tape to enhance the strength of the model)

4.

5.Edit the plate and try to fit the shape on

the paper

6.Use tools in workshop and shaping the parts

divided

7.Combine the other 2 pieces make by team mates

with glue or tape

Picture 2: The outline appearance in Rhino

Picture 3: The preparation template for 3D laser cutting

Step 2: At this stage we are going to import the template model into 3D laser cutting machine with Ply Basswood with 3.0mm thickness, which we think it is more strengthen compared with simple Ply wood. Refer to other groups experience, there is always have problem with the thickness of the slot. If too tight, it can insert 1 to 3 pieces and then because the expansion property, the rest of piece will be too narrow to insert. Another hand, if it is loose then the combined majority will be less strength and the piece slip out will frequently occurred which might cause extra troubles. For this problem, after 2 times test cut, we finally found out a comfortable thickness.

After we produce it successful, there is new issues raised. The middle and top side which connect with left and right wings is too thin and possible for crack. For this situation, we decide to remove the exist figures marked on the timber piece and try to expand the thickness of the neck of our model and enhance the strength. In addition, we have cut 3 more pieces of this section for insurance the improved one crack. And finally we cost 1 of them during the proofread procedures.

Picture 4: Processing laser cutting

Picture 5 & 6: Different perspective for finish timber fuel tank model

Step 3: At this stage we are going to use tape to cover over it(expect the bottom) like a 'mummy'. This process is so important that this model now is consist of vertex and the edge, the faces of it is still void. And we use tape, despite of the stickiness, the tension it own is much more flexible. The stickiness from start and to the end binding tight with the model and offer it faces and more strength, because the viscidity of tape. With the fully tight binding, the compression take place on the model and make it more strength. Although it cost much tape in the workshop, from the result, it might be worth.

Picture 6 & 7: Different view for the tape cover the model

Step 4: After discussion we decided to divided it into 3 parts with about proportion in order to make the separation much fair and make sense. So we are try to use paper to cover it and separate it, the paper process means that the fuel tank is full of curve side and smooth, we can not measure it with simple ruler but through some media things. For the paper cover, we implied a little techniques that at the most curve sides it is required to cut the paper slide by slide and attached with yellow tape, this way can let the connection of curve much loose, which reduce the measure error for scale the aluminum material.

Picture 8: After paper cover model overview

Picture 9: Side paper scale sample (Left)

Step 5: At this stage, we have made the paper scale sample and need to use it on the aluminum material. Grab the aluminum board and cut it into roughly rectangle. Then we put the sample above the cut rectangle and try to outline a shape with mark pen. There is a notice that it is always remind to leave extra space for the project. Because the extra can be adjust or cut off, if there is too small, it is not likely to weld to fulfill the defect.

Picture 10: Mark and scale out the detailed aluminum side part

Picture 11: Raw aluminum left side part of the project

Step 6: This part will test the most skill we learnt from half semester. Because it is a irregular appearance. Some large mark i decide to pass through and try to maintain the clean surface of the product. At first, i try to make it a bit curve aim at cover the model through hammering the curve edge as a line but not a single point just like the theory of joint of skeleton. It looks like some joint line that make the product cover the wing of model. This part have cost me about 40 minutes for adjust and repair. Then the point is the top side which is need to combine with the Top one. Thus i am plan to hammer the top side of my part and make it a bit shape change to warm up for the shrinkage machine. If using the shrinkage for the flat condition, which is possible for the crack, which really damage the surface performance. After the top side shrinkage, it is ready for English wheel to make some planishing. But need to remind that the wrong pick for the degree of English wheel might cause some degree of shape change for the main product, it required some attempt. Finally try to make the balance of the top side curve and maintain the product can cover the model, it is time to cut out the extra part to reach beautiful match and combination with group members.

Picture 12 & 13: Shrinkage for the top side area and the performance

Picture 14: Failure on cover the model

Picture 15: After repair for the wrong bend

Picture 16: Cutting off redundant area

Picture 17-19: Some left side parts finished version

Step 7: Combine with other 2 pieces with group mates, top from Jay and the right side from Maggie. In order to enhance the effect and over all appearance and performance, at the inner side of the product we have attached the tape and make it more close and match.

Picture 20-22: Some finished combined work with group mates

没有评论:

发表评论